Enhance Your Organization Workflow With Reliable Industrial Scales

In today's competitive landscape, the precision of industrial scales plays a pivotal duty in improving overall service operations. Exact considering not just mitigates expensive inconsistencies across different fields, such as production and logistics, yet additionally ensures compliance with rigorous industry standards. As organizations seek to enhance efficiency, recognizing the various kinds of scales and their technological developments comes to be vital. The choice procedure can be complex, and the effects of these choices can significantly affect functional success. What aspects should be taken into consideration to make sure the right equipment is selected for your particular demands?

Relevance of Accurate Evaluating

Precise weighing is crucial in different commercial applications, as also small discrepancies can cause significant functional ineffectiveness and economic losses. Industries such as production, logistics, and food processing rely on exact dimensions to guarantee product top quality, regulatory conformity, and optimal resource monitoring. Imprecise weights can cause overflow, waste of basic materials, or inadequate supply, influencing profitability and consumer fulfillment.

In addition, precise weighing is essential for safety and security and ecological conformity. In the chemical market, incorrect dimensions can lead to improper blends, resulting in legal implications or harmful scenarios. In the food sector, exact evaluating is essential for sticking to dietary labeling demands, ensuring that customers get exact details concerning the items they acquire.

The combination of trustworthy commercial ranges not only boosts operational performance but additionally sustains data-driven decision-making. Firms that focus on precise considering can optimize inventory management, improve supply chains, and reduce expenses related to returns and revamp. For that reason, purchasing premium industrial weighing remedies is essential for organizations aiming to preserve an affordable side in today's vibrant market. Accurate evaluating eventually functions as a structure for functional excellence and sustainable development.

Kinds Of Industrial Scales

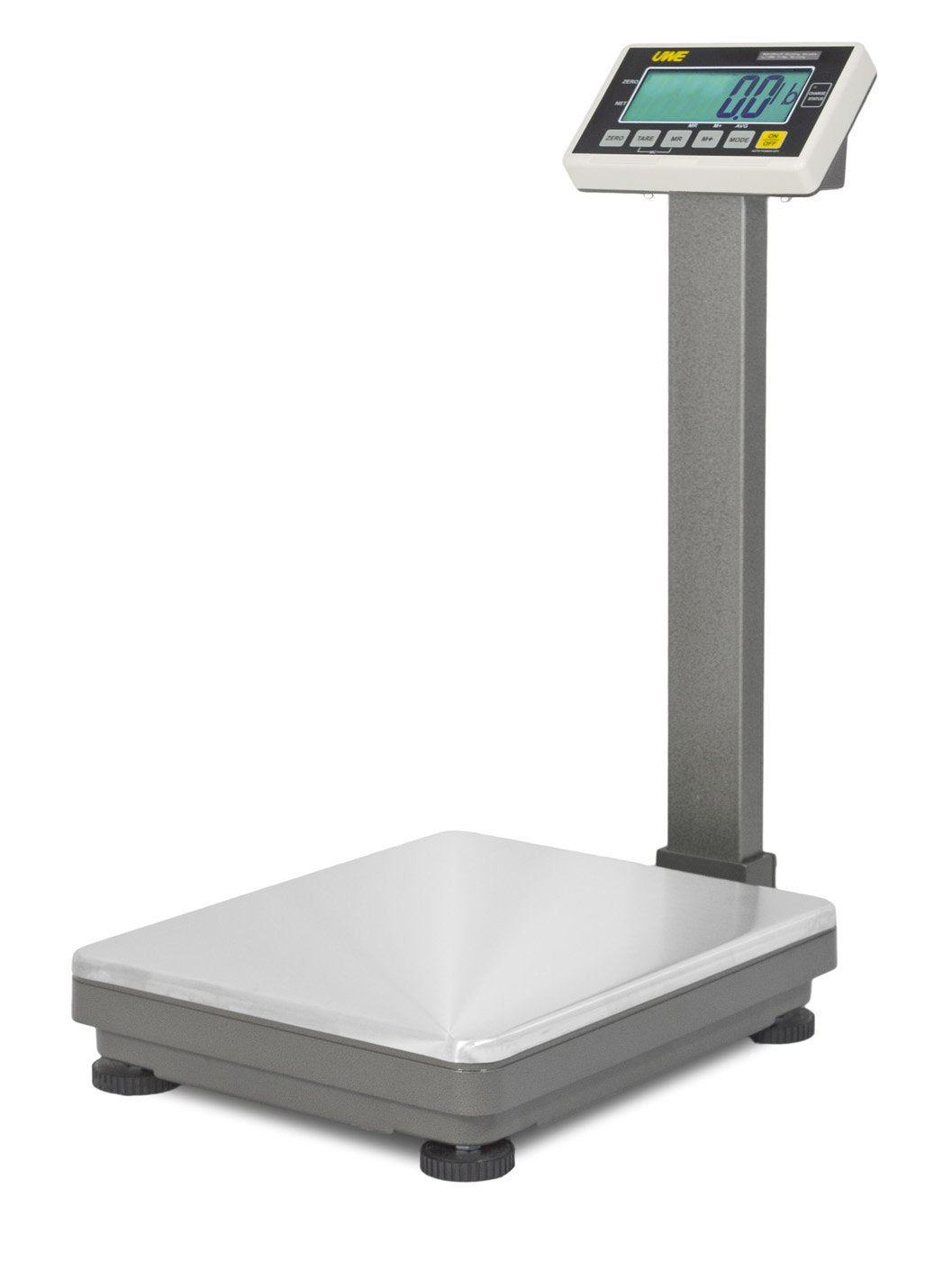

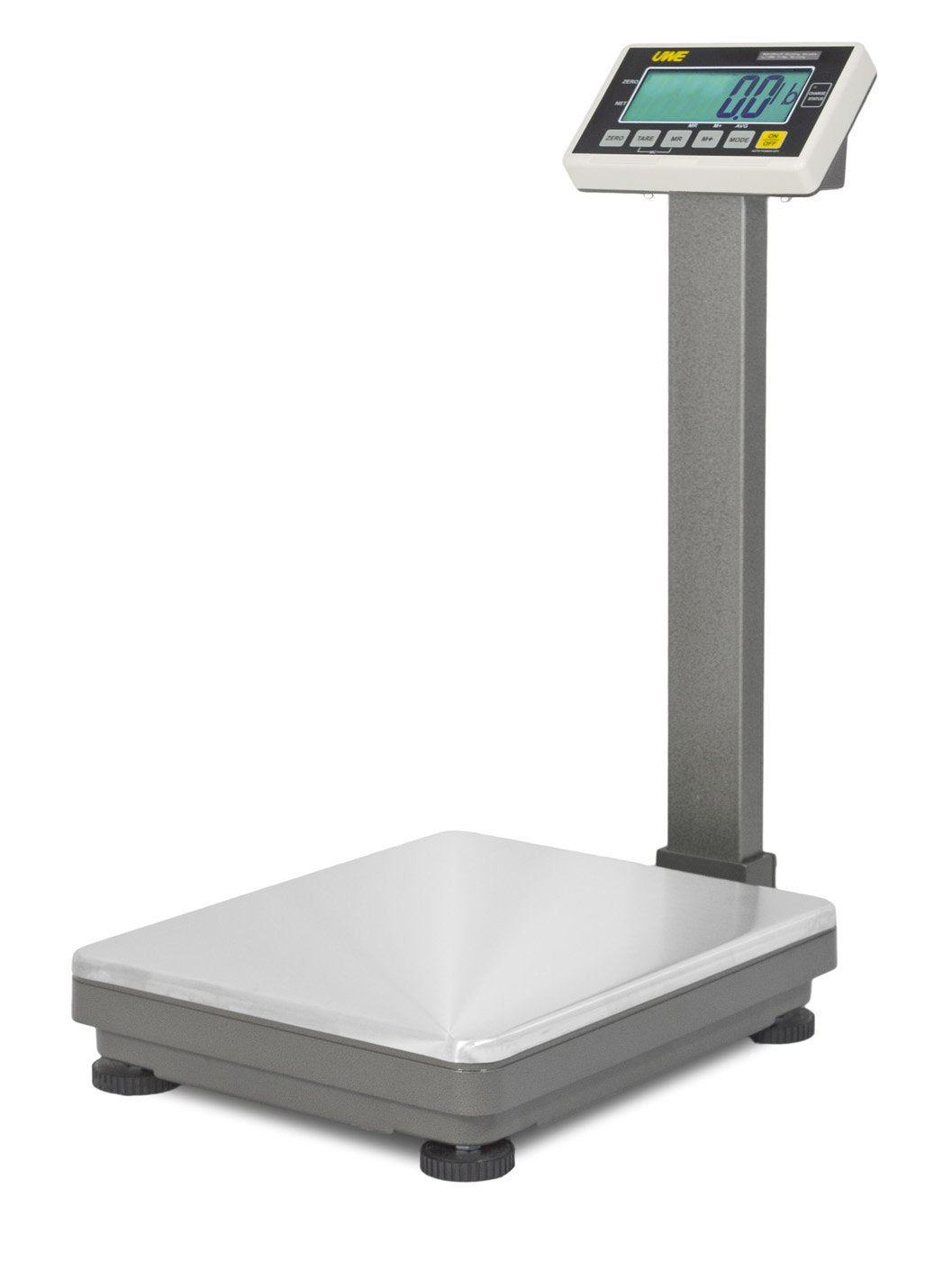

Industrial ranges come in various types, each created to satisfy certain considering requirements across different markets. Amongst one of the most typical types are platform scales, which provide a big weighing surface area appropriate for heavy items, making them perfect for warehouses and making centers. These ranges often include digital display screens for very easy reading.

One more kind is bench ranges, which are normally smaller and portable, best for usage in labs or retail settings. They permit quick measurement of smaller sized things while preserving accuracy. For applications requiring the evaluating of liquids, tank scales are especially made to gauge the weight of tank, ensuring accurate supply monitoring.

Crane scales are additionally noteworthy; they are put on hold from a structure to weigh hefty materials in commercial settings. Each type of commercial range serves a distinct objective, enhancing functional effectiveness across diverse sectors.

Advantages of Modern Technology

Moreover, contemporary commercial scales often come equipped with connection functions that make it possible for smooth combination with other systems, such as supply monitoring and manufacturing tracking. This interconnectivity cultivates a more cohesive workflow and reduces downtime, as businesses can monitor efficiency metrics and make data-driven choices promptly.

In addition, lots of contemporary ranges use adjustable setups and straightforward interfaces, enabling operators to adapt their devices for certain functional needs. Enhanced sturdiness and resilience against extreme ecological problems better add to the long life and integrity of modern scales, guaranteeing they can stand up to the roughness of commercial use.

Selecting the Right Tools

Different sectors might need distinct kinds of ranges, such as flooring ranges for heavy loads, bench scales for smaller items, or portable scales for adaptability. Additionally, considering the atmosphere in which the scales will be made use of is crucial. Tools used in severe settings may require to be rugged and resistant to dirt, wetness, or severe temperature levels.

Another critical factor is the innovation used in the scales. Digital scales usually provide improved precision and convenience of usage, while analog scales might be enough for less requiring applications. It is crucial to examine the scalability of the devices, ensuring that it can suit future development or adjustments in manufacturing procedures.

Finally, companies must take into consideration the credibility and integrity of makers, as purchasing high-quality equipment can cause long-lasting cost financial savings and enhanced functional performance.

Maintenance for Long Life

Routine upkeep is vital for ensuring the longevity and optimum efficiency of commercial ranges. A methodical approach to maintenance not just prolongs the life of the tools yet also guarantees exact dimensions crucial for functional efficiency.

Begin with routine examinations to recognize wear and tear, ensuring parts such as load cells and displays function properly. Calibration checks ought to be carried out frequently, ideally after substantial modifications in environmental problems or adhering to hefty usage. Exact calibration is essential for conformity with market standards and for preserving the reliability of weight measurements.

Cleaning is one more visit our website essential element of maintenance. Dirt, particles, and corrosive substances can impair performance and lead to mistakes. Use appropriate cleansing representatives and methods to safeguard delicate elements. In addition, it is suggested to develop an upkeep timetable that tapes each solution go to, calibration, and any kind of her response repair work done. This documentation help in tracking equipment performance and preparation for future upkeep demands.

Finally, training team on appropriate usage and care strategies will reduce the chance of operator error, even more enhancing range dependability. By focusing on routine maintenance, companies can ensure that their industrial ranges remain a trustworthy asset in their operations.

Final Thought

In summary, the combination of dependable industrial ranges is essential for enhancing company procedures across various sectors. Routine maintenance and training additional contribute to the long life and precision of these ranges, cultivating data-driven decision-making and ultimately supporting overall company success.

Industrial scales come in various types, each developed to satisfy particular considering needs across different industries. Crane scales are also noteworthy; they are suspended from a framework to evaluate heavy materials in commercial setups.Different industries may need unique types of scales, such as flooring scales for hefty tons, bench scales for smaller sized items, or portable scales for versatility - Industrial Scales. Digital scales often provide enhanced accuracy and site web simplicity of usage, while analog scales might be adequate for less demanding applications.In summary, the integration of reliable industrial ranges is essential for enhancing company operations throughout various fields

Comments on “Premier Industrial Scales Designed for Long-Term Efficiency”